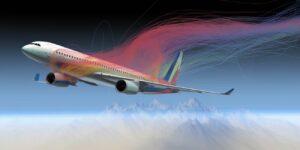

The primary purpose of an aircraft deicer is to counteract the potentially hazardous effects of freezing precipitation during flight. Ice accumulation on the wings, for instance, can disrupt the smooth flow of air over the surface, leading to decreased lift and impaired control. Now, let’s delve into the key aspects of using aircraft deicers safely and effectively.

Deicing fluids are the most common type of aircraft deicer. These fluids typically contain a mixture of glycol and water, with additional additives to enhance performance. Before applying deicing fluid, it’s crucial to conduct a thorough inspection of the aircraft’s surfaces to identify areas where ice has accumulated. This targeted approach ensures optimal use of the deicing solution and minimizes waste.

The application of deicing fluids is a meticulous process. Specialized vehicles equipped with nozzles are employed to spray the fluid onto the aircraft surfaces. The fluid effectively melts existing ice and creates a protective layer to prevent further accumulation. Pilots and ground crews must follow specific guidelines regarding the quantity and application technique to guarantee the safety and integrity of the aircraft.

One critical consideration in using aircraft deicers is the environmental impact. Deicing fluids contain chemicals that can be harmful to the environment if not managed properly. Airports and airlines adhere to strict regulations for the disposal and treatment of used deicing fluids to mitigate ecological consequences. Responsible usage involves employing environmentally friendly formulations and adopting efficient drainage systems.

Additionally, the timing of deicing procedures is crucial. Ideally, deicing should be performed as close to takeoff as possible to maximize the effectiveness of the protective layer. However, unforeseen delays or changes in weather conditions may necessitate reapplication. Efficient communication between ground crews and flight operations is paramount to adapting to dynamic situations.

Understanding how what is an aircraft deicer fluids work to remove ice

When winter blankets the runway in a frosty embrace, the challenge for aircraft to navigate the icy terrain becomes a critical concern. In the frosty battleground between aviation and winter weather, aircraft deicer fluids emerge as the unsung heroes, wielding the power to thwart the icy grip of Jack Frost on an airplane’s surfaces.

The science behind these magical elixirs lies in their ability to melt away the icy shackles that threaten the safety and functionality of an aircraft. Deicer fluids are specially formulated concoctions designed to combat freezing temperatures and ensure a smooth departure into the skies.

One of the primary components in these mystical brews is glycol, a versatile and potent compound that serves as the backbone of many deicing solutions. Glycol possesses a unique property – it lowers the freezing point of water, preventing ice from forming on the aircraft’s surfaces. As the aircraft glides through the sub-zero air, the deicer fluid forms a protective shield, preventing the formation of hazardous ice accumulations.

But the magic doesn’t stop there. Imagine the deicer fluid as a vigilant guardian, standing watch on the aircraft’s wings and tail. When the cold threatens to encase these vital components in a frozen armor, the glycol-based solution springs into action, creating a barrier that repels the ice and keeps the aircraft agile and ready for takeoff.

One might wonder – how does this enchanted elixir adhere to the aircraft’s surfaces without being swept away by the rushing wind? The answer lies in the formulation of the deicer fluid, which includes special additives and thickeners. These components grant the fluid a remarkable ability to cling to vertical and horizontal surfaces, ensuring comprehensive coverage and protection against the relentless onslaught of icy foes.

Now, picture the runway as a frozen battlefield, and the aircraft as a gallant knight preparing to embark on a perilous quest. The deicer fluid, with its glycol-laden arsenal, becomes the knight’s trusted shield, warding off the icy adversaries that threaten to impede the noble journey into the skies.

It’s essential to note that different aircraft may require different formulations of deicer fluids based on their size, structure, and the severity of the weather conditions they are likely to encounter. This tailored approach ensures that each aircraft receives the optimal protection needed to face the winter elements head-on.

Choosing the right what is an aircraft deicer product for your aircraft

Choosing the right aircraft deicer product is crucial for ensuring the safety and functionality of your aircraft during cold weather conditions. The selection process involves evaluating various factors such as the type of fluid or solution used, the efficiency of the glycol content, and the method of application, whether it’s through spray or other means.

One of the primary considerations is the type of fluid or solution employed in the deicing process. Different formulations are available, each tailored to specific temperature ranges and environmental conditions. It’s essential to understand the characteristics of the deicing fluid to ensure optimal performance.

Moreover, the glycol content in the deicer solution plays a crucial role. Glycol is known for its antifreeze properties, preventing ice formation on the aircraft’s surface. Higher concentrations of glycol often result in more effective deicing, but it’s vital to strike a balance to avoid potential negative effects on the aircraft’s materials.

When it comes to the application method, spray deicers have gained popularity for their efficiency and uniform coverage. The spray application ensures that the deicing solution reaches all critical surfaces of the aircraft, preventing the accumulation of ice and frost. This method is particularly effective in rapidly changing weather conditions.

Understanding the compatibility of the chosen deicing product with the aircraft is paramount. Not all aircraft are designed to withstand the same deicing solutions, and using an incompatible product can lead to damage. Consulting the aircraft manufacturer’s guidelines and recommendations is a crucial step in the decision-making process.

In some cases, the choice of glycol concentration and deicing method may be influenced by environmental considerations. Eco-friendly deicing solutions are gaining traction, offering effective ice removal while minimizing environmental impact. It’s essential to explore options that strike a balance between performance and ecological responsibility.

| Factor | Consideration |

|---|---|

| Fluid/Solution | Choose based on temperature range and environmental conditions. |

| Glycol Content | Balance concentration for optimal deicing without causing harm. |

| Application Method | Consider spray for efficient and uniform coverage. |

| Compatibility | Consult aircraft manufacturer guidelines for suitable deicing products. |

| Environmental Impact | Explore eco-friendly options for responsible deicing. |

Proper storage and handling of what is an aircraft deicer chemicals

When it comes to the handle, store, and dispose of aircraft deicer chemicals, meticulous attention to safety and environmental considerations is paramount. These chemicals play a crucial role in ensuring the safe operation of aircraft during icy conditions, but their improper management can pose significant risks.

The handling of aircraft deicer chemicals demands a well-thought-out approach. Personnel involved in this process should undergo thorough training to understand the potential hazards and the importance of adhering to guidelines. Protective gear, including gloves and goggles, must be worn to prevent direct contact with the chemicals. It is also crucial to have designated areas for handling, minimizing the risk of accidental spills or leaks.

Proper storage of these chemicals is a critical aspect of aviation safety. Dedicated storage facilities equipped with climate control mechanisms are essential to prevent degradation of the chemical compounds. Utilizing appropriate containers, such as corrosion-resistant drums, ensures the integrity of the stored deicers. Segregating different types of deicer chemicals within the storage facility is imperative to prevent chemical reactions that could compromise their efficacy.

When the time comes to dispose of aircraft deicer chemicals, a meticulous approach is once again required. Environmental regulations dictate the proper disposal methods, and non-compliance can lead to severe consequences. Chemicals must be treated as hazardous waste, and only authorized disposal facilities should handle the process. Recycling options should be explored whenever possible to minimize the impact on the environment.

Guidelines for the handle, store, and dispose phases must be clearly communicated and consistently followed by all personnel involved. Regular audits and training sessions help reinforce these guidelines, ensuring a culture of safety and responsibility within the aviation industry.

See also: